MTP® vs MPO Cable: Understanding the Differences

In the field of fiber optic connectivity, MTP® and MPO cables play a vital role in supporting high-bandwidth and high-density wiring systems.

While they may seem similar, there are important mechanical design differences that set them apart.

In this article, we will explore the dissimilarities between MTP® and MPO cables, shedding light on their unique features and benefits.

MPO Cable

MPO (Multiple-Fiber Push-On) cables are equipped with MPO connectors on both ends.

These connectors are designed to provide multi-fiber connections within a single connector, making them ideal for high-density applications in data centers and LAN environments.

MPO connectors typically come with 8, 12, 16, or 24 fibers, commonly used in various networking applications.

For professional ultra-high-density multiplexing, larger switches can utilize MPO connectors with 32, 48, 60 or even 72 fibers - known as fiber arrays.

MTP® Cable

MTP® (Multi-Fiber Termination Push-On) cables also feature MTP® connectors on both ends.

The MTP® connector, a trademark of US Conec, represents an enhanced version of the MPO connector with improved mechanical and optical performance.

MTP® connectors are fully compatible with standard MPO connectors, allowing seamless interconnection with other MPO-based infrastructure.

However, MTP® connectors offer additional engineering enhancements that enhance their capabilities.

Distinguishing Features

-

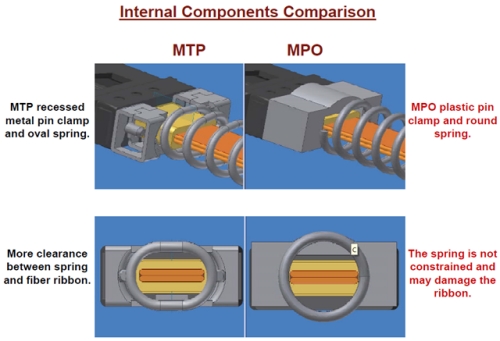

Pin Clamp: MPO connectors typically have plastic pin clamps, which can be prone to breaking when repeatedly mated. In contrast, MTP® connectors utilize a metal pin clamp that provides a secure hold on the pins, minimizing the risk of accidental breakage during mating. The MTP® connector also incorporates an oval spring to protect the fiber ribbon from damage during insertion.

-

Floating Ferrule: MTP® cables employ a floating ferrule design, allowing the ferrule to float inside and maintain physical contact under an applied load. This feature is absent in MPO connectors. The floating ferrule is particularly beneficial for applications where the cable plugs directly into active Tx/Rx devices, making the MTP® connector well-suited for emerging parallel optics Tx/Rx applications.

-

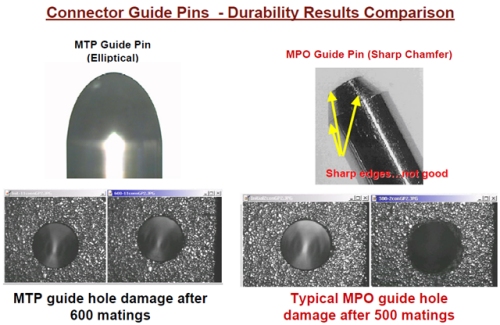

Guide Pins: Multi-fiber connectors rely on guide pins for coarse alignment. MTP® connectors utilize stainless steel elliptical guide pin tips with tight tolerances to reduce the risk of debris falling into the guide pin holes or onto the ferrule end face. In contrast, MPO connectors use chamfered-shaped guide pins, which may generate more debris during usage.

How to Choose Between MTP and MPO Cable

MTP® and MPO cables are widely used in high-bandwidth and high-density applications.

While MTP® connectors are an enhanced version of MPO connectors, both serve their purposes in the industry.

The choice between MTP® and MPO depends on the specific requirements of the application and the desired level of mechanical and optical performance.

It's important to note that the fiber optic industry is continuously evolving, and advancements in manufacturing, assembly, polishing, cleaning and testing techniques are constantly improving.

As a result, components assembled using alternate suppliers can achieve higher performance levels than standard specifications.

Flexibility in collaborating with multiple component suppliers is crucial to delivering high-performance solutions.

When comparing competitive product lines, emphasis should be placed on performance claims rather than specific brand names of the components.

As industry standards evolve and new technologies emerge, staying informed about the latest advancements in MTP® and MPO connectivity will ensure optimal performance and reliability for your fiber optic network.

Contact us for more informations!