Guide of MPO Patch Cable

In the face of increasing demands for high-speed and high-capacity optical communication systems, MTP/MPO fiber connectors and fiber patch cables have emerged as ideal solutions for meeting the high-density cabling requirements in data centers.

Their advantages, such as high fiber count, small form factor and high transmission rates, have made them a popular choice.

In this article, Fibeye will provide a detailed overview of MPO patch cables, covering their definition, applications and important considerations during the installation process.

1. What is an MPO Patch Cable?

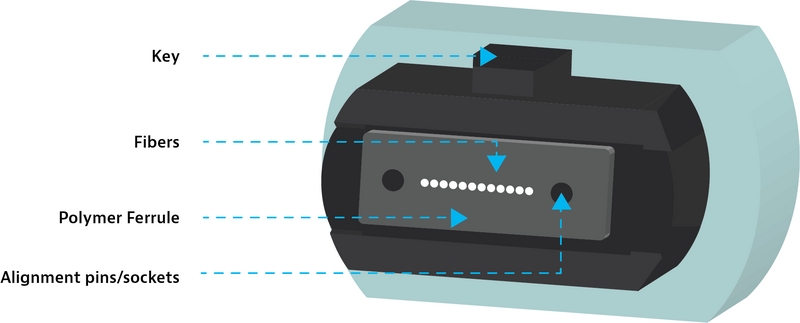

An MPO (Multi-fiber Push-On) patch cable is a type of fiber optic cable that utilizes MPO connectors.

MPO connectors are part of the MT (Mechanical Transfer) connector series, which feature precision alignment through two 0.7mm guide holes and alignment pins on the ferrule end face.

MPO connectors can be used with various types of fiber optic cables to create MPO patch cables.

These patch cables can be designed with 2 to 12 fibers, with the maximum capacity being 24 fibers.

Currently, the most commonly used MPO connector has 12 fibers. The compact design of MPO connectors allows for a higher fiber count in a smaller form factor.

2. Applications of MPO Patch Cables

MPO patch cables find applications in a wide range of settings, including:

- Enterprise LAN cabling between different buildings.

- Optical interconnections in active equipment within LANs and WANs.

- Communication links in base stations.

- Indoor cabling in distribution boxes for residential areas, industrial parks, and commercial buildings.

- Fiber optic communication systems in densely populated buildings, such as apartment complexes and commercial towers.

- FTTx (Fiber to the x) deployments.

- Cable TV networks and telecom networks.

3. Important Considerations for MPO Patch Cable Installation

During the installation process of MPO patch cables, the following points should be taken into consideration:

- Avoid removing dust caps from connectors before mating. If the connectors are connected to adapter panels but not yet mated, it is advisable to keep the dust caps in place.

- Avoid contact or scraping of connector end faces with any other objects, except during regular mating.

- If there is visible dirt or contamination on the end face, clean it using specialized cleaning tools or lint-free wipes soaked in anhydrous alcohol. Do not use tissues, cotton swabs, or ordinary cotton balls for end face cleaning.

- When mating connectors, ensure proper alignment and avoid repeated insertions and removals without visual inspection of the end face.

- When inserting MPO connectors into adapters, hold the connector by the boot. When removing them, hold the connector by the housing.

- Maintain a minimum bending radius for the cable, which should be equal to or greater than 20 times the cable outer diameter.

- When bundling cables, ensure appropriate tension to avoid excessive deformation of the cable jacket.

- When routing cables through holes or conduits, use a pushing and pulling method instead of dragging or forcefully pushing the cable to prevent scraping or cable breakage.

4. Common Types of MPO Patch Cables:

MPO patch cables can be classified into two main types: transition and non-transition.

Transition MPO patch cables come in various forms, including ribbon cables, fan-out cables (circular or square), and breakout cables that branch out into 2 to 24 fibers of 0.9mm or 2.0mm cable.

The connector type for the patch cable can be specified by the customer and can include FC, LC, SC, ST or other types.

The total length of the MPO patch cable or the branch length, as well as any other specific requirements, can be customized according to customer needs.

MPO patch cables have become indispensable in the development and practical implementation of optical networks.

With their ability to meet high-density cabling demands, they are widely employed in various applications, including data centers, enterprise networks, and telecommunications.

Fibeye offers a comprehensive range of MPO patch cables, each undergoing strict quality inspection processes such as end face inspection, insertion loss and return loss testing, and 3D interferometer testing. Contact us today to explore our MPO patch cable solutions!